Events

Convening Legislators from Seven States Around Circular Economy Solutions in Montréal

August 21, 2025

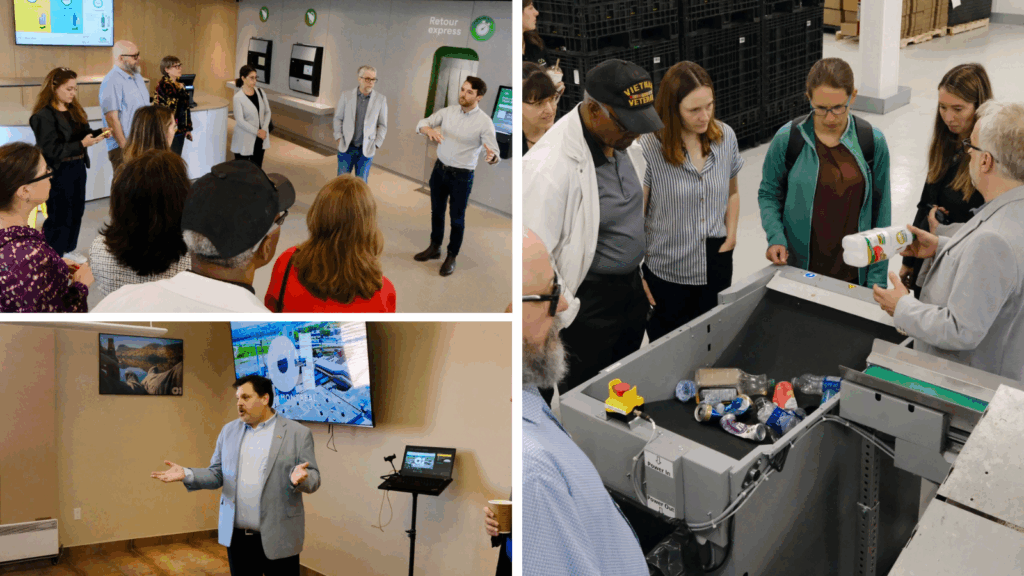

On June 9-12, NCEL members gathered in Montréal, Canada, to participate in the OPLN CIRCLE Expeditionary Summit, an immersive three-day convening and tour focused on waste reduction solutions. CIRCLE, an initiative of the Ocean Plastics Leadership Network (OPLN), is committed to advancing knowledge and building capacity for effective circular economy policies. Seven legislators — from seven states spanning from Hawaii to Vermont — gained insights into recycling and material management while learning about best practices for extended producer responsibility (EPR) and deposit return system (DRS) policies and implementation.

Day 1, June 10: From Curbside to Recovery

Material Recovery Facility

The first day of the Expeditionary Summit began with a tour of GFL Environmental’s Material Recovery Facility (MRF) in Montréal East. Newly opened in January 2025, the facility is the largest and most technologically advanced in Québec, processing 52 tons of residential single-stream recycling per hour. Although Québec has had curbside recycling for about three decades, the new GFL MRF is the province’s first facility to meet the standards of the curbside recycling program under Québec’s modernized EPR framework.

- Impact & Implementation: Legislators learned that the GFL MRF accepts all types of plastic, as well as cartons, glass, various grades of fibers, and more. Participants witnessed the fruits of significant investments in automation, although the facility still uses a combination of mechanical and human sortation, employing 90 workers.

Lavergne: E-Waste Recycling

In the afternoon, legislators had the unique opportunity to tour a Lavergne facility specializing in the recycling of plastics from e-waste. President and CEO Jean-Luc Lavergne shared how his company works closely with a number of brands to recycle hard plastics while stripping wires and recouping the metal.

- Impact & Implementation: While the Lavergne facility also recycles automotive materials, they are best known for building its business on a closed-loop system as part of HP’s printer ink cartridge recycling program. Frances Edmonds, Head of Sustainable Impact at HP Canada, also delivered a presentation on HP’s circular economy work, noting that HP is already 40% circular with a goal of 70% circularity by 2030.

Day 2, June 11: Policy in Practice

During the second day of the trip, panels showcased EPR and DRS work in both Québec and Canada more broadly.

Extended Producer Responsibility

The morning began with an in-depth presentation from the province’s Producer Responsibility Organization (PRO), Éco Entreprises Québec’s (ÉEQ), a private nonprofit representing Québec producers that manages their financial responsibilities for curbside recycling. Legislators learned about the key components of the Québec EPR system, including regulatory targets, PRO governance structure, and the role of the PRO in managing and paying for the system. ÉEQ also outlined innovations and investments in the recycling system and financing methodologies such as base fees and eco-modulation.

After lunch, lawmakers gained perspective on the broader system through a panel with guests from several Canadian PROs: Recycle BC for British Columbia, ÉEQ, and Circular Materials for Ontario, New Brunswick, Alberta, and the Yukon Territory.

- Takeaways: Legislators learned about some of the challenges facing Canadian PROs around harmonization across provinces, investments in infrastructure, and containing costs. Independent EPR regulators from Ontario and Alberta shared insights into their unique role in ensuring companies comply with EPR law. As independent regulators, they are accountable to the government, separate from producers, and have government-like prosecutorial powers.

Strengthening Reuse and Return

The final part of the day shifted gears, starting with Québec’s deposit return system.

- Deposit Return System: Attendees learned about ConsignAction, the public-facing brand for the DRS system, and the Québec Beverage Container Recycling Association (QBCRA), Québec’s PRO. Together, they are implementing a phased system expansion as more materials and beverage types are brought under the deposit system. One goal within the expansion is for 90% of Québec’s population to have a depot within 15 minutes of where they live.

- Supporting Valorites: Next, legislators had the opportunity to hear about Coop Les Valoristes (CLV), a nonprofit organization focused on encouraging and supporting valorites – people who recover refundable, recyclable, or reusable materials for economic, social, and/or environmental reasons. The organization provides valoristes with a dedicated space to sort and redeem containers and rest, while providing a connection to social services.

- Reuse Pilots: To round out the day, the Circular Innovation Council and the Canada Plastics Pact shared case studies of recent reuse pilots in Canada. The Circular Innovation Council led a pilot in Ottawa for reusable containers in grocery stores, and four months into the project, the system reached a 95% return rate. Meanwhile, the Canada Plastics Pact has been working on programs for reusable food packaging at Canadian universities, windshield washer fluid available at gas and charging stations, and reusable packaging for household goods.

Day 3, June 12: Modernizing Recovery Systems

ConsignAction Recycling Depot

The final day of the Expeditionary Summit began with a visit to a newly opened ConsignAction recycling depot. Legislators toured the site, where the design focuses on the customer experience. Participants also learned about the infrastructure that supports Québec’s recent deposit return system modernization.

- Impact & Implementation: Recent updates to Québec’s system have raised most deposits to 10 cents (glass bottles larger than 500ml have a 25-cent deposit), brought in more material types such as plastic bottles, and made more beverages eligible for a deposit refund, including water, juice, and spirits. In addition, the shift to a depot-based system increases transportation efficiency by decreasing the number of retailer stops trucks need to make.

O-I Glass Plant

For the final stop of the trip, legislators toured Montréal’s O-I glass plant, which has been in operation for 120 years. The plant recycles glass containers for a variety of applications, from maple syrup to spirits. O-I staff highlighted glass’ benefits as an inert, recyclable, and safe material.

- Impact & Implementation: Participants learned that O-I is increasing the amount of cullet – the industry term for recycled glass – used in production. For each 10% increase in cullet used in manufacturing, energy needs are reduced by 3%, which also extends the lifespan of furnaces.

Looking Ahead: Bringing Circular Solutions Home

Legislators from the NCEL network gained new insights and tangible solutions from their experience in Montréal. The group expressed excitement for bringing back what they learned to their states as they pursue EPR and DRS legislation, implementation, and modernization.

This year, at least 12 states have introduced 30 pieces of packaging EPR legislation, while 17 states and D.C. have introduced 52 pieces of DRS legislation. Maryland (SB 0901) and Washington (SB 5284) became the sixth and seventh states to enact packaging EPR in 2025, while Hawaii passed an EPR needs assessment (HB 750) and Rhode Island enacted a needs assessment for both EPR and DRS (H 6207/S 996).